How Biofoundries are Accelerating Life-Enhancing Innovations in Biomanufacturing

Advanced research labs stocked with interconnected, automated technologies are enabling rapid development of new products across a wide range of industries.

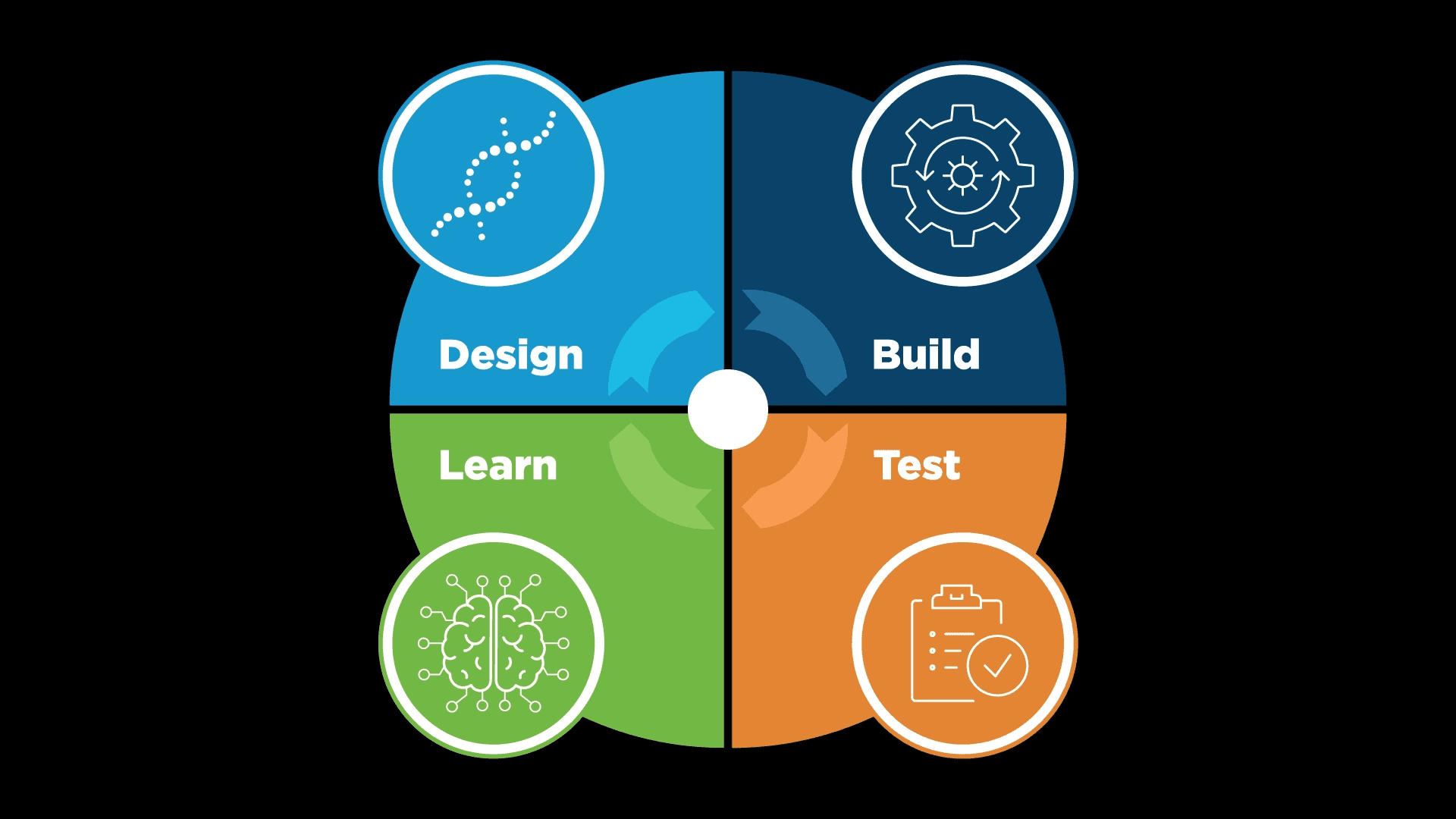

Traditional cycles of innovation in synthetic biology involve many repetitions of steps we refer to as “design, build, test, learn (DBTL).” After the last step, we take what we learn and apply it to the next iteration of the design, repeating the cycle until we get it right. It’s a laborious and often costly process, but it’s vital to driving the next generation of genomic innovations—DNA and RNA advances that will yield not just medical advances, but also new foods, fuels and materials.

The biotech industry is rapidly evolving to improve the efficiency of these cycles to speed up the development of the most promising innovations. A key element of that evolution is the growth of biofoundries—highly automated, in-house research laboratories built to accelerate the DBTL cycle in genomic discovery and development.

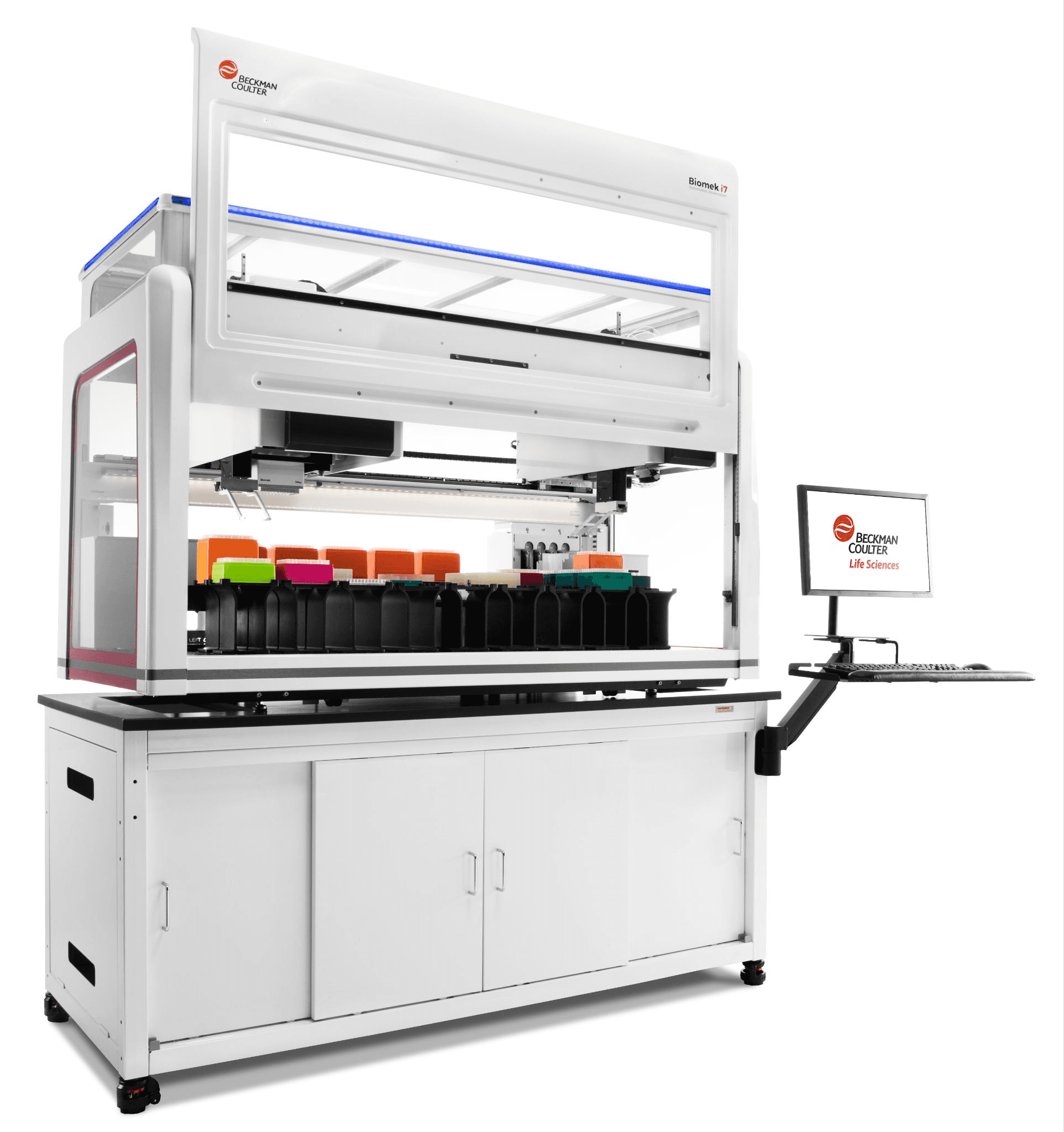

A typical biofoundry is equipped with state-of-the-art technology and advanced instrumentation, providing an integrated infrastructure that enables high-throughput, multidisciplinary research and supports the rapid design, construction, and testing of genetically reprogrammed organisms for biotechnology applications. Capabilities include DNA and RNA sequencing, flow cytometry, high-throughput colony picking, clone screening, and cell culturing, among others. Originally developed to accelerate the search for biologically produced alternatives to conventional industrial processes, biofoundries are now also being applied to the advance medical innovation and healthcare solutions.

Interconnected Technologies

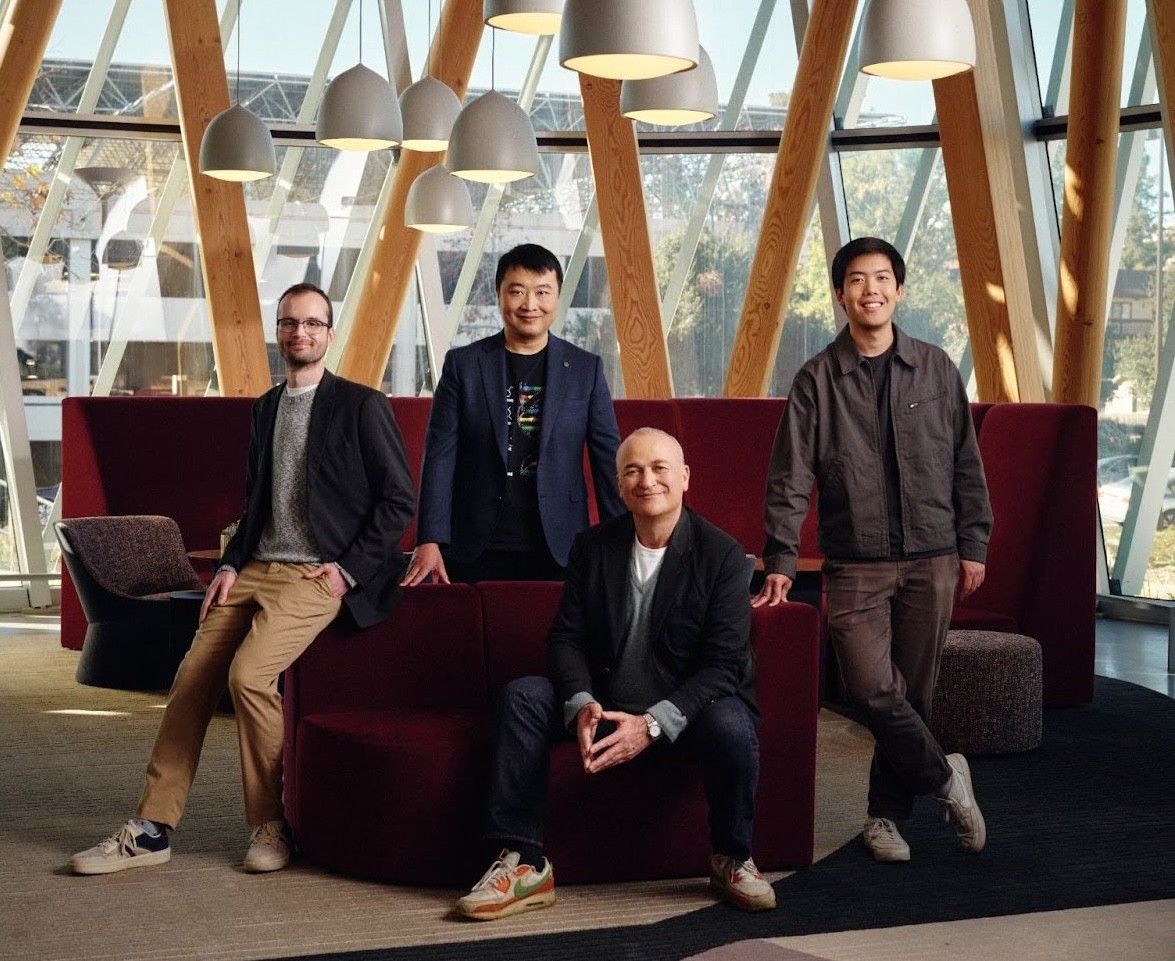

While biofoundries receive funding from public, academic, and private sector sources, Lesaffre stands out as a prominent example of a private company that has built and operates its own substantial facilities. Lesaffre is a France-based global provider of yeast, yeast products, flavors, fragrances, nutraceuticals, and pharmaceuticals made by precision fermentation. Its biofoundry has the capacity to perform 20,000 growth-based assays per day, with automatic monitoring of enzyme activity or cell growth multiple times per day. The facility’s robots were programmed with software specially tailored to its researchers’ needs and connected to the company’s laboratory information management systems and electronic lab notebooks. The biofoundry includes more than 100 interconnected programmable instruments supporting eight work cells.

This technology has enabled Lesaffre to work hand-in-hand with a wide range of customers to accelerate innovations. For example, the company works with manufacturers of baked foods to optimize different strains of yeasts to improve production.

“Access to these tools has increased our screening capacity from 10,000 [yeast] strains per year to 20,000 per day. Genetic improvement projects that previously required five to 10 years can now be completed in six to 12 months,” says Massimo Merighi, former Chief Bioengineering Officer of Lesaffre and General Manager of Recombia Biosciences. “Biology is still not easy to engineer, but the automation solutions we adopted and have perfected allow us to do things that were unthinkable just a few years ago.”

From Food to Fuel

The ability to quickly modify yeast strains is also beneficial to developers of renewable resources, including alternative fuel. For example, novel enzyme technologies and yeast fermentation can be used to convert carbon-based feedstocks, waste or agricultural residues into renewable ethanol. Optimizing yeast strains helps improve ethanol production yields, which ultimately will reduce the world’s dependence on fossil fuels and lower pollution.

In the future, biofoundries could contribute even more rapid innovations that benefit the environment. Several startups are developing bio-made fibers that can be used as alternatives to petroleum-based polyester, a material that requires fossil fuels to manufacture and that isn’t biodegradable. They include Solena, a British company that’s designing new proteins that can be used to make biodegradable fibers. And a few years ago, a team of University of Copenhagen students developed biodegradable fishing nets made from spider silk, sea anemone and mussel proteins. Their project, aimed at reducing sea pollution, won the iGEM Grant Prize, which is awarded to researchers who use synthetic biology to develop innovative solutions for unsolved issues. CJ Bio in Korea manufactures bio-plastics based on PHA for a range of consumer products; they commissioned a biofoundry in 2022 like Lesaffre. Genomatica has accessed the bio-based polymers markets for nylon and polyesters thanks also to their partnership with the Ginkgo Bioworks biofoundry. To some extent the future promised by the biofoundry approach to bioengineering is already here.

The Future of Biofoundries

The next stage of biofoundry evolution is the incorporation of physical and generative artificial intelligence (AI) into research technology. At Lesaffre, AI applications are being employed to improve high-throughput screening, troubleshoot robot performance, decipher the relationship between structure and function in enzyme production and more, Merighi says.

The growth of new biomanufactured products has raised some challenges, including the need to establish regulatory standards and metrics, and the need to build the capacity necessary to scale up innovations into manufacturable products. The emergence of pilot plants and of consortia seeking unified approaches to these challenges reflects a growing momentum. One example is the Global Biofoundry Alliance, a group of more than 25 organizations that was launched in 2019 with the goal of coordinating biofoundry activities worldwide.

Ultimately, the Global Biofoundry Alliance strives to create an open-source model that allows new technologies and capabilities in synthetic biology to be widely shared. Among the beneficiaries will be startups that may have not been able to afford these tools in the past.

This widespread access to sophisticated technology infrastructures will accelerate innovations from all over the biotechnology ecosystem—yielding new products that enhance lives across the globe.