The past decades have seen a sharp rise in obesity, diabetes, and Metabolic syndrome, especially among younger and younger children. Experts and non-experts alike are attributing this trend to the sugar in our diets -- refined, added sugars to be precise. Artificial sweeteners such as aspartame hit the scene years ago but are villainized as much as sugar due to fears about negative health effects and the increased demand for “clean label” products.Enter stevia leaf extract, the seemingly perfect solution. It’s natural because it comes from a plant (Stevia rebaudiana), healthy because it has no calories, and economical because it’s hundreds of times sweeter than sugar -- a little goes a long way.But stevia leaf extract isn’t so perfect. The first-generation product, which has been on market for around a decade, hasn’t garnered as much customer acceptance as expected. Why? Sweet though they are, first-generation stevia sweeteners suffer from a bitter, licorice-like aftertaste.The optimal solution, it seems, would be a pure, natural sweetener that lacks the licorice aftertaste and tastes more like sugar. An impossible challenge? At least one company doesn’t think so.

The ultimate solution: Enzymatic reorganization of steviol glycosides

Boston-based Conagen Inc. -- a leader in the bio-manufacture of high-value ingredients for the food, pharmaceutical, and renewable markets industries -- has its sights set on natural sweeteners, which CEO Oliver Yu described in 2017 as “by far” the biggest short-term opportunity space for biobased products in the U.S. Since then, Conagen has achieved important breakthroughs in the space.

Oliver Yu, CEO of Conagen, at SynBioBeta SF 2017.The major components of stevia leaf extract are steviol glycosides. Stevioside is the major component, followed by small to trace amounts of rebaudiosides, which give the extract its sweet taste. The major rebaudioside constituent of stevia leaf extract is Reb A, although several other rebaudiosides are also present in trace amounts. The Conagen team has learned that one trace rebaudioside, called Reb M, can provide the superior taste profile they believe is necessary for a successful, next-generation natural sweetener.“The distinctive aftertaste that was associated with those first-generation stevia products can no longer be found with the next-generation rebaudiosides like our Reb M,” says Matt Mattozzi, Manager of Scientific Operations at Conagen.

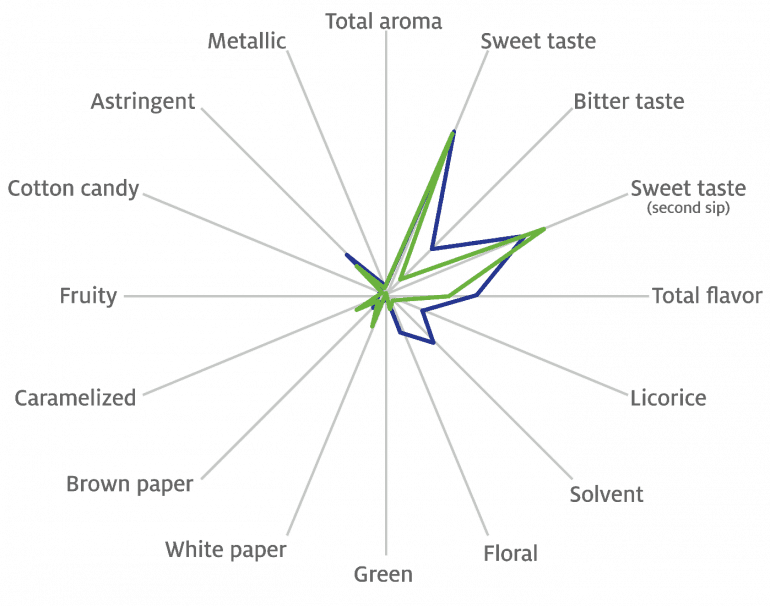

An external sensory panel determined that RebM (above in blue) has a superior taste profile compared to RebA (above in green), much closer to the taste of sugar.But it’s one thing to identify a superior rebaudioside. It’s quite another to turn it into a product -- and a pure one at that.

Combining ancient processes with modern biotechnology

Conagen leverages fermentation -- an ancient microbial process -- to manufacture their suite of products, currently around 35. Through their integrated manufacturing chain, the team can move from design to high-throughput screening and fermentation rather quickly -- a useful capability when it comes to producing Reb M.“We do an enhanced bioconversion,” says Mattozzi, “wherein we take the extract from the leaf, and through enzymatic conversions we push what starts as a trace amount of Reb M to over 95% purity.”Put that way, the process sounds simple. But it was only possible due to the team’s ability to test hundreds of different enzymatic processes in a high-throughput way. Why hundreds?A critical characteristic of all rebaudiosides is the number of glycosyl groups found on the stevial core of the molecule, which affect the taste profile of the rebaudioside. Reb M has six glycosyl groups; several other rebaudiosides -- Reb E, Reb V, Reb D, and Reb I, to name a few -- have four or five glycosyl groups attached, making them potential Reb M precursors, and flavoring enhancers and sweeteners in their own right. How those groups are oriented and sequentially added to the steviol backbone yields hundreds of different combinations -- all of which the Conagen team tested for the desired output: the best flavor. They then optimized growth conditions for each bio-conversion process.“This has allowed us to access the mixture of different steviol glycosides that are already in the natural extract to converge them down on to Reb M,” explains Mattozzi. “Synthetic biology at work.”The result? A commercial product called BESTEVIA® Reb M stevia leaf sweetener.

Third-generation natural sweeteners?

While the Reb M sweetener is a novel, improved solution, the Conagen team isn’t stopping there. They have identified a number of trace compounds in the stevia leaf extract that actually have more glycosyl groups -- seven and even eight -- than Reb M, which should make them sweeter and potentially give them an even more palatable taste profile than Reb M. Mattozzi sees these more complex glycosides as potential third-generation natural sweeteners within Conagen’s grasp based on their success making Reb M.Regardless of what the future holds for the next generation of natural sweeteners, Conagen is in a good position to lead the way. As Mattozzi puts it, “Our knowledge on plant biochemistry, strain development, and fermentation allowed us to develop this process. However, it was our experience of scaling up processes that enabled us to develop a commercial product like BESTEVIA® Reb M.”