Food Agriculture

Halting Deforestation With Synthetic Biology-Produced Fats

Sustainable technologies like fermented and cultivated fats could meet the global demand for lipids without the adverse ecological impacts

[GPT-4o]

The world has a seemingly insatiable appetite for fats. Beyond food production, tallow is used as a fuel, industrial lubricant, and raw material for various industrial chemicals. Palm oil, derived from palm trees in large monoculture plantations, has applications in food, personal care, pharma, and textiles, among other sectors.

But this high demand for fats comes at a massive ecological cost. “Livestock farming for tallow and lard drives deforestation, consumes vast amounts of water and feed, and generates significant greenhouse gas emissions,” said Sonalie Figueiras, a food futurist and founder and editor-in-chief of impact media platform Green Queen. Similarly, she added, “Palm oil production has led to massive habitat destruction in Southeast Asia.”

Figuerias is also Chair of the Food and Ag Track at SynBioBeta: The Global Synthetic Biology Conference, taking place this week at the San Jose Convention Center. She created a session to address this very topic entitled “The Lipid Problem: How Synbio Can Help Make Oil & Fat Supply Chains Deforestation-Free,” in which several commentators in this article will be participating.

Now, in a bid to mitigate these impacts, companies are using synthetic biology to produce animal and plant fat alternatives with a considerably lower footprint.

Producing Fats Without Agriculture

Compared to proteins, fats are simpler molecules. For instance, fat molecules have one or no chiral centers, which makes them structurally more straightforward. This means they can be produced with simple, non-biological reactions. “We have a lot of tools for combining carbon, hydrogen, and oxygen to make all kinds of other molecules, but we don't specifically combine them on our own to make food,” said Kathleen Alexander, CEO of San Jose-based startup Savor.

For example, carbon dioxide captured from the air has been turned into fuels, alcohols, and plastic precursors using heat. Savor uses this thermosynthetic approach to make fats from scratch. Their technology takes carbon dioxide or methane and water and converts them into intermediate molecules like syngas and, eventually, long-chain synthetic hydrocarbons. “We transform those hydrocarbons into fatty acids and then fats and oils,” said Alexander.

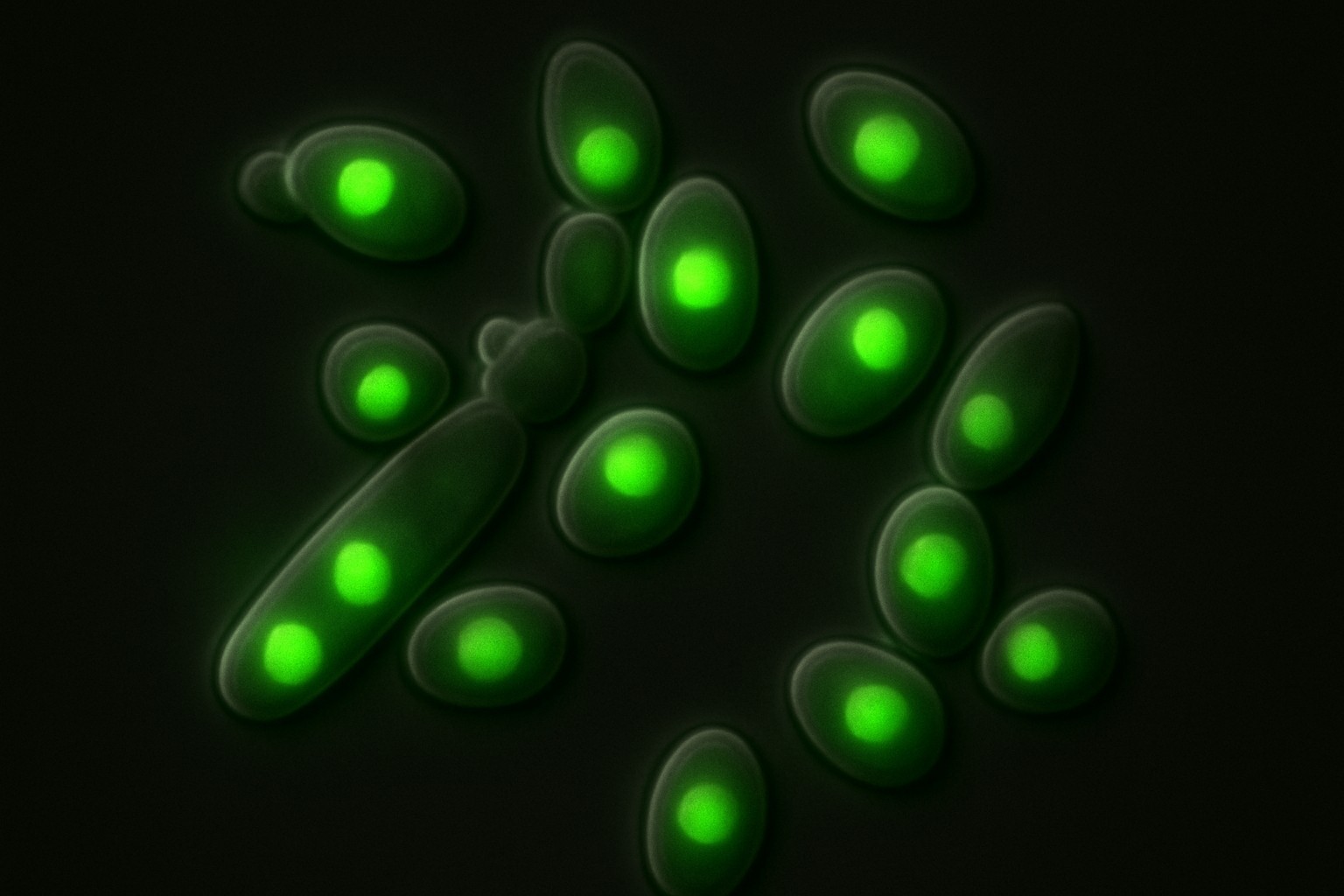

Many microbes are oleaginous, which means they produce excess lipids. Companies like Dutch biotech NoPalm Ingredients are augmenting the fat-producing capabilities of these microbes to turn them into a sustainable fat source. “We use directed evolution to improve the performance [of oleaginous yeast strains] and do some strain optimization,” said NoPalm CEO Lars Langhout.

“We create palm oil without palm trees by fermenting food industry side streams using yeast,” said Langhout. This makes their method circular and, in combination with deploying the kind of fermenters used in breweries, keeps capital expenditures low. Langhout added that their technology reduces carbon emissions by 96% and land use by 99% while achieving cost parity with traditional palm oil production.

Cultvated fat is another approach for sustainable fat production. Just like cultivated protein is grown with muscle cells, fats can be grown by culturing adipocytes or fat cells. Precursor cells are isolated from an animal, coaxed to differentiate into adipocytes, and nourished in bioreactors.

“Startups like Hoxton Farms and Mission Barns specialize in growing fat cells, which mature much faster than muscle cells, reducing production time and costs,” said Figueiras. “Cultivated fat also allows for precise control over marbling and composition, enabling premium products like lab-grown wagyu beef.“ Unlike air-captured or fermented fats, which are being developed to replace traditional fats in different sectors, research on cultivated fats is primarily limited to dietary applications.

Sustainable Fats For Food And More

Although cultivated meat has been generally regarded as synonymous with cultivated protein, fats are also an important aspect of meat. The fat content contributes to the nutritional benefits and sensory experience of eating meat. Fat gives meat its juiciness, tenderness, and distinct flavor. Mixing cultivated fats with cultivated protein, or even vegan protein, could make meat substitutes more palatable and appealing to consumers.

However, “If you want to produce a fat that mimics animal fat, you'd need to produce a similar fatty acid profile,” said Langhout. While NoPalm doesn’t serve this niche, their fermentation platform is flexible to make fatty acids mimic animal-derived fat. The simpler chemical structure of fats means that tweaking their production is convenient, regardless of the technology.

Unlike proteins, fats also see wider use in the industry. This is both an advantage and an opportunity. “You can tap into a broad set of markets and a broad set of functional properties that people are looking at from fats and oils,” said Alexander. For instance, Savor produces milkfat, cocoa butter, and alternatives to beef tallow and palm oil. NoPalm also makes alternative fats for food and personal care use cases.

Palm oil alternatives from Savor, NoPalm, and other companies could reduce reliance on palm oil from plantations. Likewise, animal-free fats could be used in drug delivery systems or nutritional supplements. Moreover, “The biofuels sector is exploring cultivated lipids as sustainable aviation fuel. There’s also potential in biomaterials, where fat-derived polymers could replace petroleum-based plastics,” said Figueiras.

Deforestation-Free Fat Supply Chains

When it comes to public dietary perception, protein occupies a haloed space unmatched by fats or carbohydrates. This is likely part of the reason why the alternative proteins received greater interest before alternative fats, despite the latter being easier to synthesize. But this also means that the ecological impact of fat supply chains receives less interest as compared to that of raising livestock for meat.

Deforestation due to palm oil plantations and other plant and animal sources of fats has wide-ranging ecological impacts. The loss of habitat exacerbates biodiversity losses and greenhouse gas emissions. Sustainable fat alternatives could change that. Speeding up the adoption of alternative fats, particularly cultivated fats, would require faster regulatory approvals as they help build consumer and investor confidence. ”Cost reductions through scaling up fermentation and bioreactor technologies and off-take agreements with the big FMCG companies will also be critical,” said Figueiras.

However, such agreements, Langhout noted, represent a chicken-and-egg problem for the upcoming sustainable fat alternatives industry. “Our customers want large volumes. But the investors, to enable us to build such volumes, want to see off-take agreements,“ said Langhout. Thankfully, there have been positive developments in the space recently. NoPalm partnered with FMCG Colgate-Palmolive to create soaps out of fermentation-derived palm oil alternatives, and Savor launched its butter made from air.

As customers expect more eco-friendly alternatives and the technologies scale up, more companies will launch products made with air-captured, fermented, and cultivated fats. Synthetic biology is heralding a future where fats don’t come with a side of deforestation.