‘Living’ Concrete Paves the Way for More Sustainable Structures

Drexel University's "BioFiber" innovatively turns concrete fibers into living tissue with "concrete-healing" bacteria, promising longer-lasting structures and improved sustainability

AI Image Created Using DALL-E

Across the natural world, from the single-celled ‘Stentor’ to the colossal giant redwood Sequoiadendron giganteum, living organisms demonstrate the remarkable ability to heal. Wounds can be patched, broken bones fused, and, in some cases, entire body parts regenerated, all in the name of longevity. With a visionary twist on traditional concrete reinforcement techniques, researchers at Drexel University’s College of Engineering sought to bring this capability to the world of man-made materials, specifically concrete. Inspired by the innate regenerative properties found in living tissues, their approach transforms reinforcing fibers into a living tissue system that swiftly delivers concrete-healing bacteria to the site of cracks. This evolution in construction materials, reported in the journal Construction and Building Materials, not only promises to fortify the longevity and resilience of concrete structures but also underscores the potential for merging biological principles with cutting-edge engineering solutions.

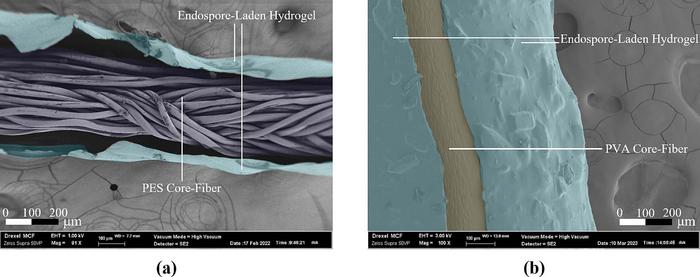

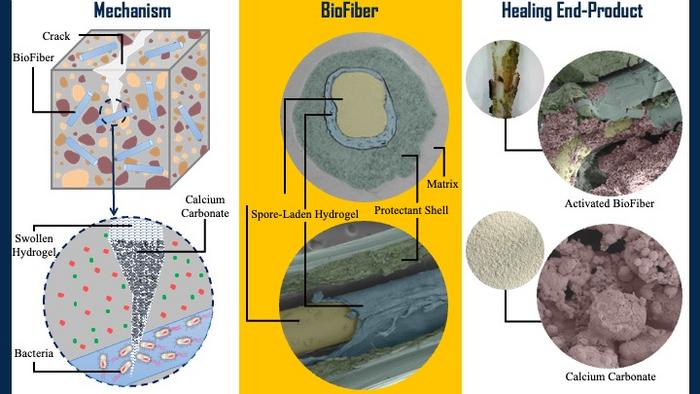

Drexel's "BioFiber" introduces a polymer fiber encased in a bacteria-laden hydrogel and a protective, damage-responsive shell. The research team reports that incorporating a grid of BioFibers into a concrete structure can enhance its durability, impede crack propagation, and facilitate self-healing.

"This is an exciting development for the ongoing efforts to improve building materials using inspiration from nature," remarked Dr. Amir Farnam, an associate professor in the College of Engineering and a research team leader. "Imagine, they can heal themselves? In our skin, our tissue does it naturally through a multilayer fibrous structure infused with our self-healing fluid — blood. These biofibers mimic this concept and use stone-making bacteria to create damage-responsive living self-healing concrete."

Extending the lifespan of concrete is not merely a boon for the construction sector; it has become a global imperative in the quest to curb greenhouse gas emissions. The production of concrete ingredients, involving the combustion of minerals at temperatures exceeding 2,000 degrees Fahrenheit, contributes 8% to global greenhouse gas emissions. Exacerbating this issue is the suboptimal lifespan of concrete. Despite being the most consumed and sought-after building material globally, concrete is susceptible to degradation within 50 years, depending on environmental factors. Prolonging its longevity presents a substantial stride in mitigating its impact on global warming, and the U.S. Department of Energy has recently initiated efforts focused on this crucial improvement. Over the past decade, Drexel has been at the forefront of this movement, and Dr. Farnam's lab is actively involved in a Department of Defense initiative aimed at fortifying aging structures.

"The BioFiber project represents a collaborative, multidisciplinary endeavor, integrating expertise from the fields of civil engineering, biology, chemistry, and materials science," noted Mohammad Houshmand, a doctoral candidate in Farnam’s lab and the lead author of the research.

Inspired by the self-healing capability of skin tissue and the role of vasculature systems in aiding wound healing, the team employs a biological technique to enable self-repair in concrete infrastructure, leveraging biomineralizing bacteria. Collaborating with research teams led by Dr. Caroline Schauer, Dr. Christopher Sales, and Dr. Ahmad Najafi, all from the College of Engineering, the group identified a strain of Lysinibacillus sphaericus bacteria as a bio-healing agent for the fiber. This resilient bacteria, typically found in soil, can lie dormant until called to action when it induces a microbial process to create a stone-like material that stabilizes and hardens into a patch for exposed cracks in concrete.

“One of the amazing things about this research is how everyone comes at the problem from their different expertise, and the solutions to creating novel BioFibers are so much stronger because of that,” Schauer said. “Selecting the right combination of bacteria, hydrogel, and polymer coating was central to this research and to the functionality of BioFiber. Drawing inspiration from nature is one thing, but translating that into an application comprised of biological ingredients that can all coexist in a functional structure is quite an undertaking — one that requires a multifaced team of experts to achieve successfully.”

The BioFiber starts with a polymer fiber core, which is then coated with an endospore-laden hydrogel and encased in a damage-responsive polymer shell. Placed in a grid throughout the concrete during pouring, the BioFiber acts as a reinforcing support agent. It reveals its true efficacy when a crack breaches the concrete enough to pierce the fiber's outer polymer shell.

As water infiltrates the crack, reaching the BioFiber, the hydrogel expands, pushing its way out of the shell and towards the crack's surface. Simultaneously, activated bacteria, responding to the presence of carbon and a nutrient source in the concrete, produce calcium carbonate, acting as a cementing material to fill the crack.

The healing time, contingent on crack size and bacterial activity, is currently under study. Preliminary indications suggest the bacteria could complete the repair in as little as one to two days.

"While there is much work to be done in examining the kinetics of self-repair, our findings suggest that this is a viable method for arresting formation, stabilizing, and repairing cracks without external intervention," asserted Dr. Farnam. "This means that BioFiber could one day be used to make a ‘living’ concrete infrastructure and extend its life, preventing the need for costly repairs or replacements."